What is a Circuit Breaker?

Circuit breaker is a automatically operating safety switches which operate by measuring heat or current flowing through the circuit. If that exceeds a pre-set limit, they ‘trip’ and sever the electricity supply as quickly as possible. Unlike fuses, once the fault has been rectified, they don’t require replacing and can simply be reset.

Need for Circuit Breaker

Circuit breaker is an absolutely essential part of any electrical system. Used in conjunction with proper grounding, they can safeguard against electrocution. Circuit breaker also protect appliances, wiring and property against fire hazards and other damage resulting from abnormal current flow, short circuiting, overloading, and heat build-up.

Circuit Breaker Design and Components

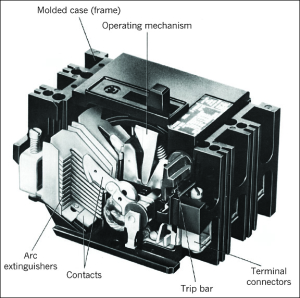

Almost all circuit breakers have five basic components:

1. External Casing : This is the external shell that encases the other parts. Based on the rated current and voltage, they are further divided into three types:

Molded Case: Typically used in low voltage circuit breakers

Insulated Case: Used in circuit breakers rated for medium voltage and amperage

Metal Clad: Generally for the higher end of the medium-rated circuit breakers

2. Electrical Contacts : There are two contacts in a circuit breaker – a fixed contact and a floating contact (which is controlled by the circuit breaker). When the breaker trips, the floating contact moves away from the fixed contact and disconnects the electricity supply into the circuit.

3. Electrical Arc Extinguishing Mechanism : When the contacts disconnect, electricity can jump through the gap between the last parts in contact. This creates an arc of electricity that can reach very high temperatures. To prevent damage and keep the arc from recreating itself, a circuit breaker uses an arc quenching mechanism to stop these arcs.

4. Main Operating Mechanisms : Circuit breakers can use a variety of methods to disconnect power supply. These can include spring-loaded switches, solenoids, hydraulic and pneumatic switches.

5. Trip Elements : Current flowing through a circuit creates heat and a magnetic field. Trip elements are calibrated to use either or both these factors to gauge the current and voltage and trip a switch, in case the maximum ratings are exceeded.

Types of Circuit Breaker

There are many types of circuit breaker designs and they can be classified on the basis of voltage (high, medium and low) or other characteristics like their arc quenching media and operating mechanism:

Arc Quenching Media

1. Oil-Based Circuit Breaker: In oil-based circuit breakers, both the contacts are submerged in insulating mineral oil. When the breaker trips and the contacts disconnect, the resulting arc vaporizes the oil, which decomposes and forms a barrier of compressed hydrogen around the arc. This prevents further arcing after the circuit is broken.

Bulk oil circuit breakers use a larger volume of oil for both arc quenching and insulation, while minimum oil circuit breakers use smaller volumes of oil, only as an interruption medium.

2. Air Circuit Breaker: Air circuit breakers can be used for low-voltage and some medium-voltage circuits too. They operate by increasing the arc voltage, which is the minimum voltage required to maintain an arc. Once it reaches a point greater than the supply voltage, the arc collapses.

These breakers are classified into two types -plain air and air blast. Depending on the design, they can achieve arc interruption by either cooling the arc plasma, increasing the length of the arc must travel, or splitting a single arc into multiple arcs.

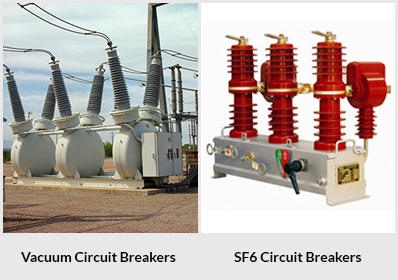

3. SF6 Circuit Breaker: These circuit breakers derive their name from sulfur hexafluoride (SF6), which is an excellent insulator that absorbs negative ions. The chamber around the contacts is filled with the gas and electrical arcing causes a chemical reaction that increases the arc voltage.

SF6 circuit breakers usually use one, two or four interrupters, depending on the voltage level they need to handle. These are not typically considered environment-friendly, since SF6 is a greenhouse gas.

4. Vacuum Circuit Breaker: Though they’ve been around for over half a century, vacuum circuit breakers are still a work in progress. They’re almost exclusively used in medium voltage circuits because of their compact size and high reliability and low maintenance.

The arc interruption takes place in a steel chamber with symmetrically placed ceramic insulators, where a very high vacuum is maintained.

Breaker Operating Mechanism

1. Thermal Circuit Breaker: Thermal circuit breakers use heat as a measure of current flowing through a circuit and disconnect once it reaches beyond a certain temperature. Two strips of different metal are joined together to form a strip that completes the circuit. As the current increases, the metals heat up and they expand at different rates, causing the strip to deform and toggle a switch, which disconnects the power supply.

Once the breaker has cooled sufficiently, the switch can be manually operated to resume the power supply to the circuit. These kinds of breakers are not instantaneous and there is a lag period between overloading and disconnecting

2. Magnetic Circuit Breaker: These breakers rely on electromagnetic energy created by electricity to trip a switch and disconnect power supply. The interrupter is connected to the switch and held in place by a spring. As the current flows through the breaker, the electromagnetic field generated becomes stronger.

Once it exceeds the breaker’s maximum rated capacity, the magnetic force overcomes the spring’s potential energy and the switch is tripped. Magnetic circuit breakers disconnect almost as soon as the circuit is overloaded, and unlike thermal breakers, they can be reset immediately too.

3. Hybrid Circuit Breaker: Combining both magnetic and thermal circuit breakers, hybrid circuit breakers can combine the advantages of both. They use magnetic breakers for instantaneous protection from surges and short circuits, as well as thermal breakers to prevent overheating from prolonged heavy loads.

Voltage Ratings

Each circuit breaker is designed to handle a certain range of voltage, so they can also be categorized on the basis of their voltage rating:

1. High Voltage Circuit Breaker: While there isn’t a global standard, according to the International Electrotechnical Commission (IEC), circuit breakers for controlling high-power transmission lines are rated for 72.5 KV and higher. Single-pole circuit breakers allow a single phase to be disconnected, which can improve stability and reduce overall failure time. High-voltage direct current (HVDC) circuit breakers are used to handle the power generated and fed from renewable sources.

These types of breakers usually use solenoid-operated or disconnecting circuit breakers, and because of the heavy loads, they incorporate sophisticated arc-quenching media like SF6 and CO2. Since safety is critical for higher voltage, high-voltage circuit breakers almost always use a variety of fail-safes, which include:

Current transformers with protective relays

Overload and ground fault protection

Enclosures that are kept at line potential (live tank) or earth potential (dead tank)

2. Medium Voltage (MV) Circuit Breaker: Circuit breaker rated between 1 and 72 KV are categorized as medium-voltage circuit breakers. Lower rating breakers (like those for indoor use) are generally installed in metal-enclosed switch-gears, while larger ones that protect feeder lines from substations are individually installed as components.

Parameters for MV breakers are governed by international standards, like the IEC 62271, and almost always use protective relays and current sensors instead of thermal or magnetic breaking mechanisms. MV breakers can be further classified by their arc-quenching media:

Vacuum circuit breakers have rated currents over 6,300A and a voltage rating of up to 40.5KV. They generally last longer and require less maintenance.

Air circuit breakers are also rated for currents of 6,300A and over, though they often incorporate adjustable trip levels and delays. They’re often used in industrial applications for main power distribution.

SF6 circuit breakers have gained popularity over oil arc-quenching media because of growing environmental concerns over oil spills

3. Low Voltage Circuit Breaker: LV breakers are used when the maximum voltage is about 1000Vac, and include miniature circuit breakers (MCB). They’re most often used in households and offices, and can be installed in tiers on a switchboard or a switchgear cabinet for easy access, resetting and replacement. Molded case circuit breakers use thermal or magnetic overload sensors and are available for ratings up to 2,500A.

Low-voltage circuit breakers are of three types :

Type B will trip when subjected to 3 to 5 times of the full load current

Type C can handle heavier loads, between 5 to 10 times of the full load current

Type D has the heaviest load handling capacity, between 10 and 20 times the full load current.

Fault Interrupters

Circuit breakers are designed to handle different faults, depending on their intended usage:

Ground Fault Current Interrupters : These are used to provide additional protection for circuits that may inadvertently come in contact with water. GFCIs measure current flowing both to and from the circuit to detect any current leaks or ground faults, which occur when an appliance falls in water, or a person comes directly in contact with live circuits.

Arc Fault Circuit Interrupters : Arcing occurs all the time, even when you flip a switch off. AFCIs are smart interrupters that can differentiate between normal arcing and unusually strong arcing. If the breaker detects an arc that is potentially dangerous, it quickly disconnects power to the circuit and prevents short-circuiting and fire hazards

Make sure you Know the difference between AFCI vs GFCI and where to use them correctly.

Miniature Circuit Breaker

MCBs are the most commonly used circuit breakers in low voltage circuits. Within a single circuit, there can be multiple smaller circuits, each controlled with an MCB, so in case of a fault only the affected circuit is disconnected. They’re more reliable and sensitive than fuses, and much easier to operate, since they can just be switched back on after the fault is rectified.

Methods of Mounting Circuit Breaker

There are various methods used to mount and install circuit breakers, each designed to meet specific requirements. The mounting methods can be classified into the following categories:

Fixed Mounted : The most affordable installations is one where the circuit breaker is wired to a load frame and bolted within an enclosure. This mounting also allows the breaker to be front mountable. These units are reliable and normally rated up to 600 Volts. Wires or sectional busbars provide power, which needs to be turned off before the breaker can be removed and replaced.

Removable Mounted : Another front-mountable installation type, a removable circuit breaker is moderately priced and offers good reliability. This two-part mounting features a base that is bolted and hard-wired to the frame, where a breaker with insulated parts is plugged in to electrically mate with it. Also appropriate for 600 Volts or less, this mounting method allows the circuit breaker to be removed and replaced with ease, but the load needs to be turned off first.

Drawout Mounted : Like removable breakers, drawout mounted circuit breakers feature a two-part design – a bolted and hard-wired base with an electrically mated plug-in breaker. The major difference is that these circuit breakers can be used with all voltages, and they are the most costly variant. Drawout mounted breakers are interlocked for safety, so the power automatically turns off when a single unit is removed, as opposed to disconnecting the power supply for all the circuit breakers installed in large enclosures.

These units are also quite large and bulky, and their weight makes them difficult to manipulate by hand. For installation and removal, they are normally moved by using a jacking screw and then hoisted onto a support that can take the extra weight. They can be replaced without disconnecting the power, but testing and removal requires the load to be turned off.